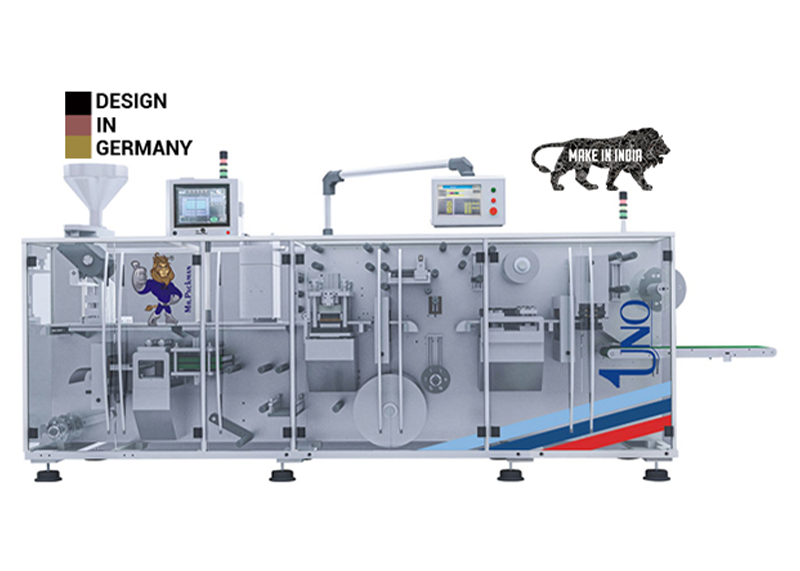

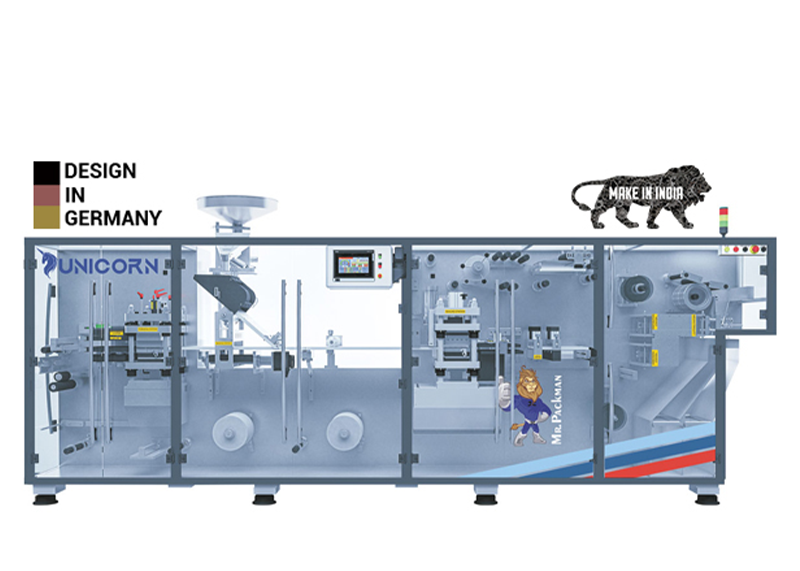

1 in Segment-PRC operated BASE FOIL & PRINTED FOIL SIMULTANEOUSLY

Production capacity up to 1.2 million Tablets-Capsules/

Shift 8 Hr. Quick tool less changes over.

Clean & Low Noise functioning of all stations due to servo controlled drive.

All In One Package Thermo Forming & Cold Forming

(Suitable for material Like Alu-Alu/PVC/PVDC/ACLAR etc.,)

Machine equipped with phase failure detection, safety interlocks & splice table.

No Micro-Stops

One user interface for all components

Best built quality

Rigid Design

Full GMP Standard satisfying with all Stainless steel cladding

SPECIAL FEATURES

TECHNICAL SPECIFICATION

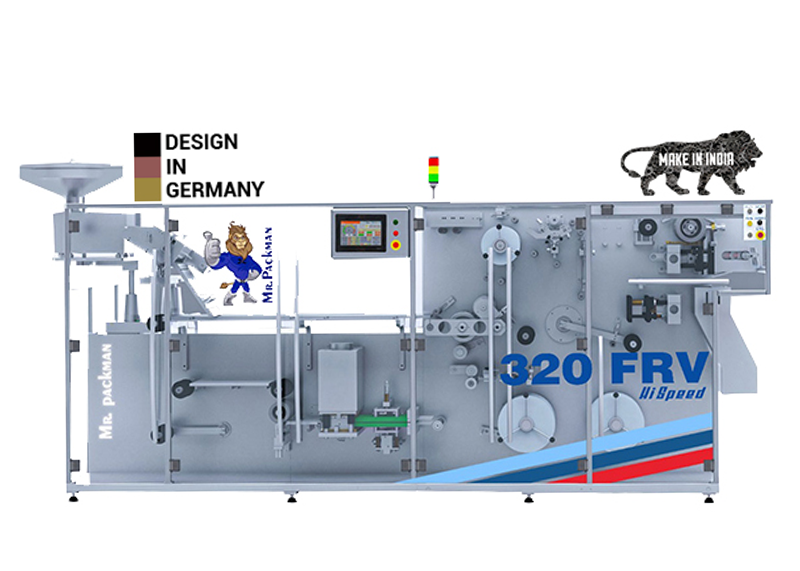

| DESCRIPTION | COLD FORMING | THERMO FORMING |

|---|---|---|

| Base Foil Width | 300 MM | 300 MM |

| Base Foil Thickness | 0.13 MM | 0.25-0.35 MM |

| Base Foil Material | Aluminum | PVC/PVDC/ACLAR/OPAQUE/TRIPLEX |

| Base Foil Reel Diameter | 440 MM (Max.) | |

| Sealing Foil Width | 300 MM | |

| Sealing Foil Thickness | 0.025 MM | 0.025 MM |

| Sealing Foil Material | Aluminum | Aluminum / CR Foil / Laminated Paper |

| Sealing Foil Reel Diameter | 220 MM (Max.) | |

| Max. Packet Forming Area | 290 X 120 MM | |

| Max. Forming Depth 10 MM 16 MM | 10 MM | 12 MM |

| Machine Speed upto | Forming Speed up to 50 strokes/Min./(depend on packet size | |

| Machine Weight | 3500 KG. | |

| Machine Size (LXWXH) | 3850 X 1250 X 2000 MM | |

| Electrical Requirement | 415 V AC, 3 Phase, 14KW, 50 Hz, 5 Core Copper wire, 4 sq. MM | |

| Earthing Cable | Copper 2.5 sq. MM | |

| Chilled Water Requirement | 2.5 Liters/min at 10º C to 16° C at 3 bar | |

| Additional Safety | Air Dryer, Voltage Stabilizer | |

| Compressed Air Requirement | 400 Liters / min at 6 bar / 15 CFM at 6 bar | |

PULSE FEATURES:

| Packing Speed | Calibrated Speed of up to 50 Strokes/Min. for Forming & 120 Strokes/ Min. for Cutting in 300 MM Format Area |

| Web Indexing | : 6 Servo Based System with roller indexing |

| Feeding | : Dropping System and Servo feeding System. |

| Man Machine Interface | : Ergonomically and User Friendly Touch Screen Operation |

| Scrap Handling | : Scrap Winder with 3 indexing servo Based Machine it helps in reducing setting time & wastage |

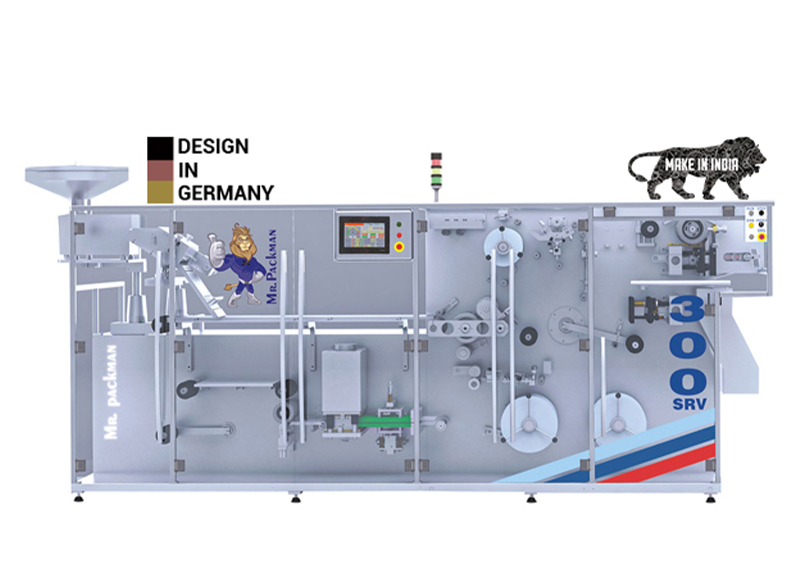

OPTIONAL FEATURES:

- PERFORATION

- BLISTER INSPECTION SYSTEM

- WITH REJECTION SYSTEM

- INKJET PRINTER

- EMBOSSING

- SP-FEEDING SYSTEM

- SCADA SYSTEM COMPLIANCE FOR 21 CFR WITH IPC