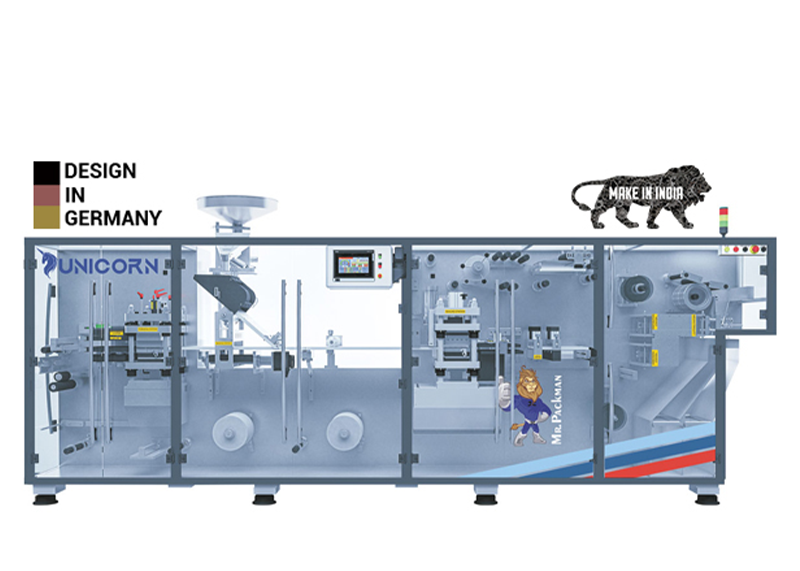

- FORMING STATION:

Intermitted flat forming - SEALING STATION:

Intermitted flat sealing - ALL WORK STATIONS, SERVO MOTOR DRIVEN

- ALL FUCNTION BY PLC

- QUICK CHANGEPART CHANGEOVER

- FEEDING ARRANGEMENTS:

- Universal brush feeder/Dedicated feeder

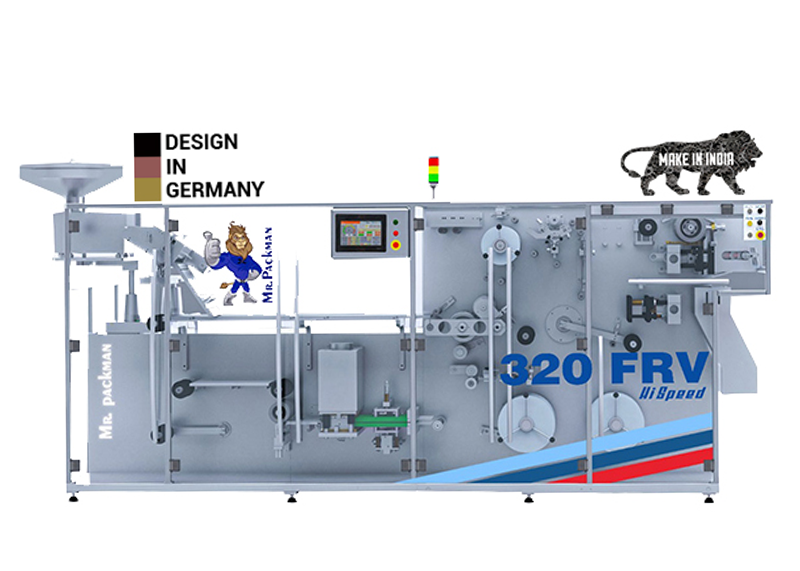

- HI Speed Machine With Dynamic Al Programming Add-Up with 6 Servo Motor for Precise Control

- Operator Friendly

- Change-Part Compatibility with other Machine

- Servo Oscillating Feeding System

SALIENT FEATURES:

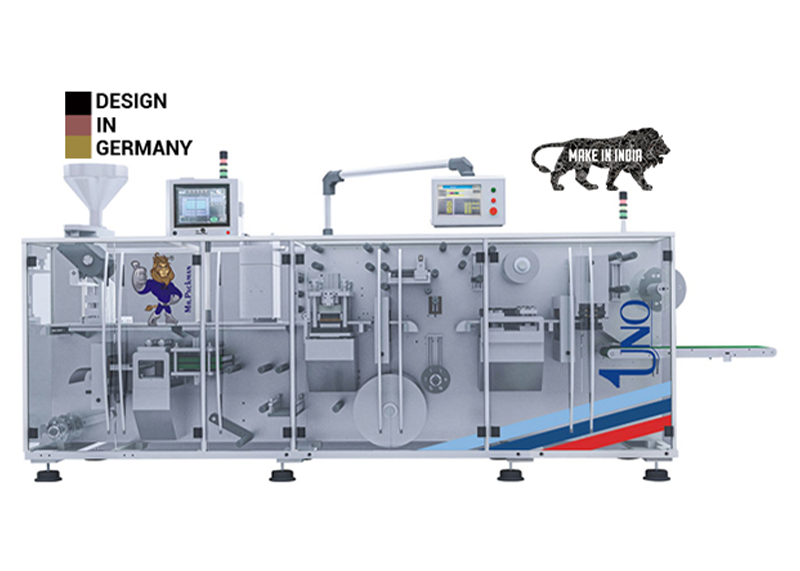

TECHNICAL SPECIFICATION

| DESCRIPTION | COLD FORMING | THERMO FORMING |

|---|---|---|

| Base Foil Width | 300 MM | 300 MM |

| Base Foil Thickness | 0.13 MM | 0.25-0.35 MM |

| Base Foil Material | Aluminum | PVC/PVDC/ACLAR/OPAQUE/TRIPLEX |

| Base Foil Reel Diameter | 440 MM (Max.) | |

| Sealing Foil Width | 300 MM | |

| Sealing Foil Thickness | 0.025 MM | 0.025 MM |

| Sealing Foil Material | Aluminum | Aluminum / CR Foil / Laminated Paper |

| Sealing Foil Reel Diameter | 220 MM (Max.) | |

| Max. Packet Forming Area | 290 X 180 MM | |

| Max. Forming Depth 10 MM 16 MM | 10 MM | 12 MM |

| Machine Speed upto | Forming Speed up to 50 strokes/Min./(depend on packet size | |

| Machine Weight | 4850 KG. | |

| Machine Size (LXWXH) | 4900 X 1050 X 2150 MM | |

| Electrical Requirement | 415 V AC, 3 Phase, 20KW, 50 Hz, 5 Core Copper wire, 10 sq. MM | |

| Earthing Cable | Copper 2.5 sq. MM | |

| Chilled Water Requirement | 5 Liters/min at 10º C to 16° C at 3 bar | |

| Additional Safety | Air Dryer, Voltage Stabilizer | |

| Compressed Air Requirement | 450 Liters/min at 6 bar | |

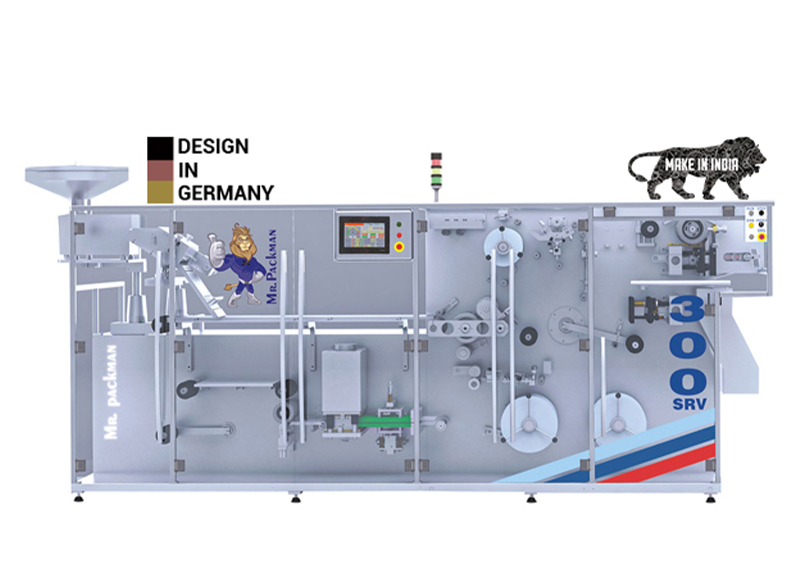

OPTIONAL FEATURES:

- PRC System

- Inkjet Printer System

- Blister Inspection System

- Polycarbonate Guard

- 21 CFR Part 11 Compliance

- CE Certification