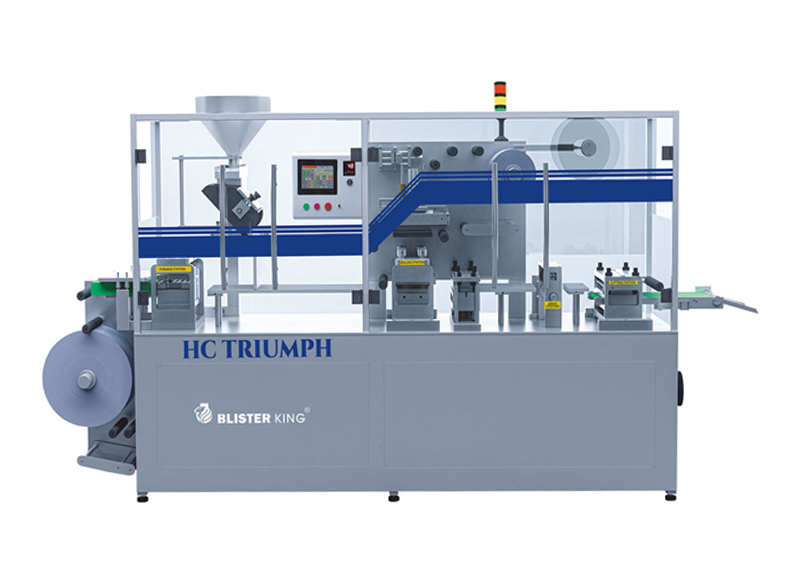

- No Micro-Stops

- One User Interface for all Components

- Best built Quality

- Rigid Design

- Full GMP Standards Satisfying with Stainless Steel

- Hi-Speed with Smoothness & Noiseless Performs

SALIENT FEATURE :

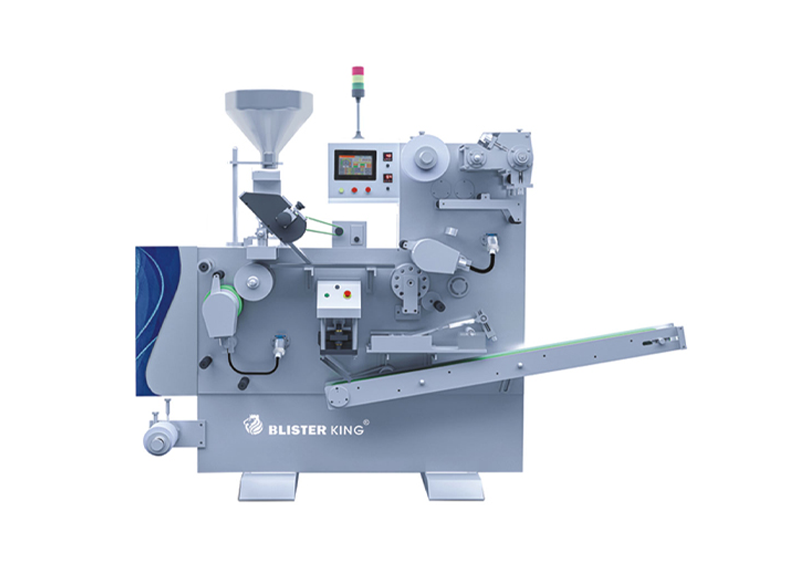

PULSE FEATURES:

- Packing Speed : Calibrated Speed of upto 30 Strokes / Min.

- Web Indexing : Servo Based System With Roller Indexing

- Feeding : Rotary Type Servo System/ Pneumatic Tick Tock Feeder

- Man Machine Interface : Ergonomically and user friendly Touch Screen Operation

- Scrap : Scrap Winder

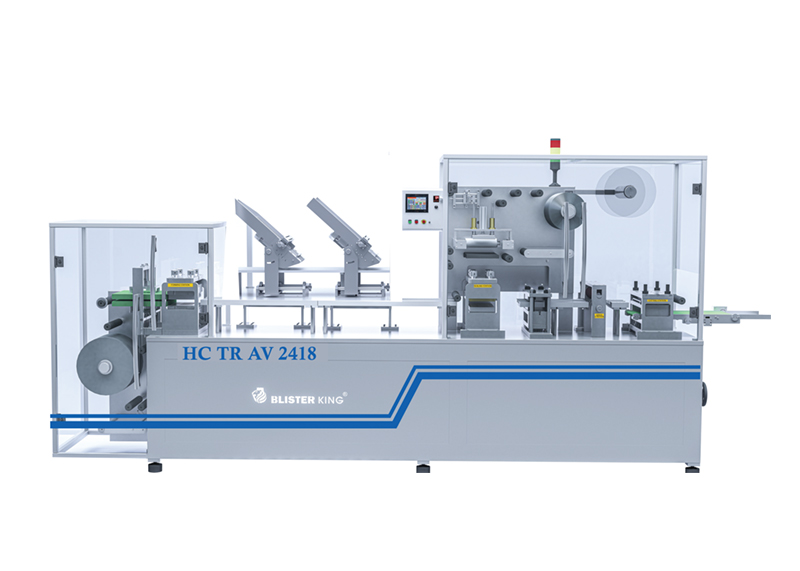

TECHNICAL SPECIFICATION

|

DESCRIPTION |

THERMO FORMING |

|

Base Foil Width Max. |

240 MM |

| Maximum output |

Upto 450 Amp/min. |

|

Base Foil Thickness Max. |

0.25 – 0.45 MM |

| Base Foil Material |

PVC / PVDC / ACLAR / OPAQUE / TRIPLEX |

|

Base Foil Reel Diameter Max. |

440 MM (Max.) Foil Reel Core Dia 72-76 MM |

| Sealing Foil Width Max. |

240 MM |

|

Sealing Foil Thickness Max. |

0.025 MM |

| Sealing Foil Material |

Aluminium / CR Foil / Laminated Paper |

|

Sealing Foil Reel Diameter Max. |

210 MM (Max.) Foil Reel Core Dia 72-76 MM |

| Format Area |

240 MMX 180 MM |

|

Max. Packet Forming Area |

230 MM x 175 MM |

| Max. Forming Depth |

28 MM |

|

Machine Speed upto |

Forming Speed 30 Strokes / Min. (Depend on pack size) |

| Machine Dimension (L x W x H) |

4200X1050X1900 MM |

|

Machine Weight |

1900 kg + 100 kg |

| Electrical Requirement |

3 Phase, 10.5 KW 400 + 5% V, 50 Hz , 5 Wire, 2.5 Sq. MM |

|

Child Water Requirement |

200 Liters of Chilled Water / Hour at 16° C Temperature |

| Additional Safety |

Air Dryer, Voltage Stabilizer |

|

Compressed Air Requirement |

Dry Air with 6-8 bar Continuous Pressure (8 CFM) |

OPTIONAL FEATURES:

- Perforation

- Blister Inspection System with Rejection System

- Inkjet Printer System

- Embossing System

- Acrylic & Polycarbonate Guard

- SCADA System Compliance 21 CFR with IPC

- In Special Case, Ectra Servo can be Loaded for Better Performance

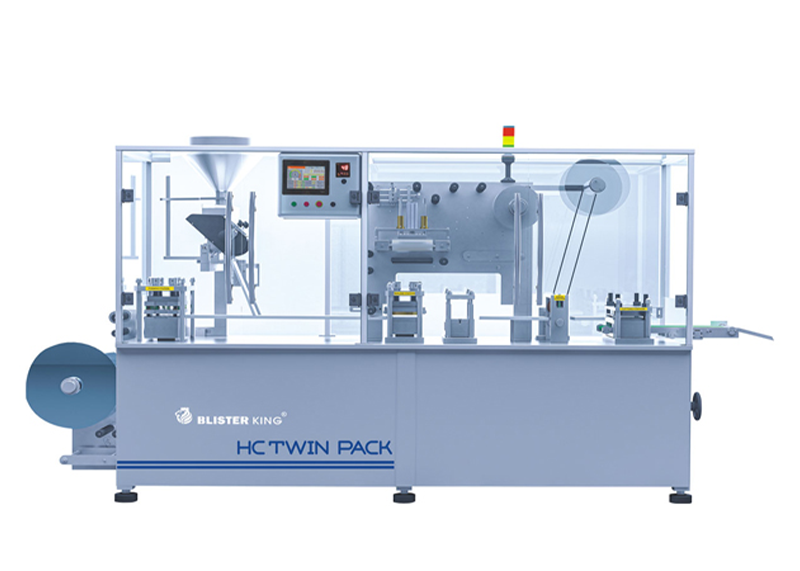

RELATED PRODUCTS