Production capacity upto 2500 Tablets per/min.

Production capacity upto 415 Ampoules-Vials per/min.

Best built quality

Rigid Design

Full GMP Standards satisfying with all Stainless

steel cladding

Hi-speed with smoothness & noiseless performance

SALINET FEATURES:

TECHNICAL SPECIFICATION

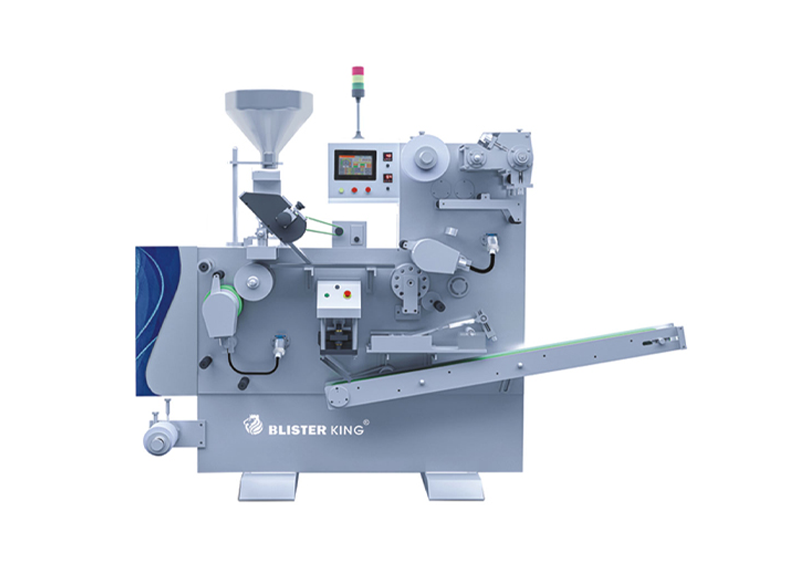

| DESCRIPTION | PVC BLISTER - 240 |

|---|---|

| Base Film Width | 210 MM |

| Base Film Thickness | 0.25-0.4 MM |

| Base Film Material | PVC/PVDC/ACLAR/OPAQUE/TRIPLEX |

| Sealing Foil Width Max. | 206 MM |

| Sealing Foil Thickness Max. | 0.02 - 0.04 MM |

| Sealing Foil Material | Aluminum/CR Foil / Laminated Paper |

| Pack Length | 200 MM |

| Pack Width | 100 MM |

| Forming Depth Ampule / Vial | 16 MM / 20 MM |

| Forming Depth for Tablet/Capsule | 12 MM |

| Max. Output | 38 MM |

| Machine Speed upto | Upto 1200000 Tablet - Capsules per shift (8 Hr.) |

| Upto 200000 Ampoule - Vials per shift (8 Hr.) | |

| Cutting Speed | Upto 100 Strokes per/min. for Tablets-Capsules |

| Upto 30 Strokes per/min. Ampoule - Vials | |

| Electrical Input | 3 Phase, 6.5 KW, 50 Hz, 5 Wire, 2.5 Sq. MM |

| Machine Size Blister 240 (L X W X H) | 2750 x 1000 x 1800 MM |

| Machine Size Blister 240 XL (L X W X H) | 3200 x 1000 x 1800 MM |

| Compressed Air Requirement | 15 CFM 6 Bar Pressure |

| Chilled Water Requirement | 100 Liters of chilled Water / Hour at 16° C Temperature |

| Additional Safety | Air Dryer, Voltage Stabilizer |

OPTIONAL FEATURES:

Perforation

Blister Inspection System With

Rejection System

Inkjet Printer

Batch Code Letter

Embossing Attachment

Auto Feeder For Ampoule – Vials

Acrylic & Polycarbonate Guards

Scada System Compliance For

21 CFR With Ipc

Print Registration Control (PRC)

For Pack To Print

PLC Based Operation

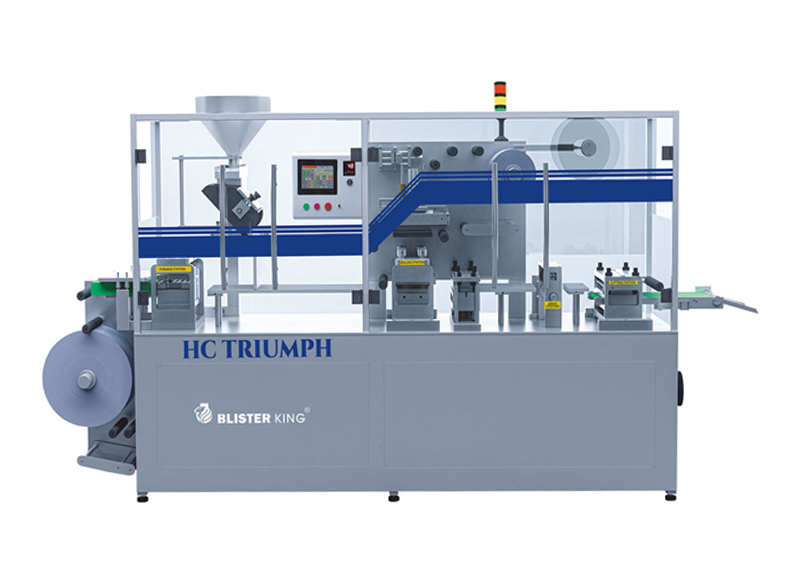

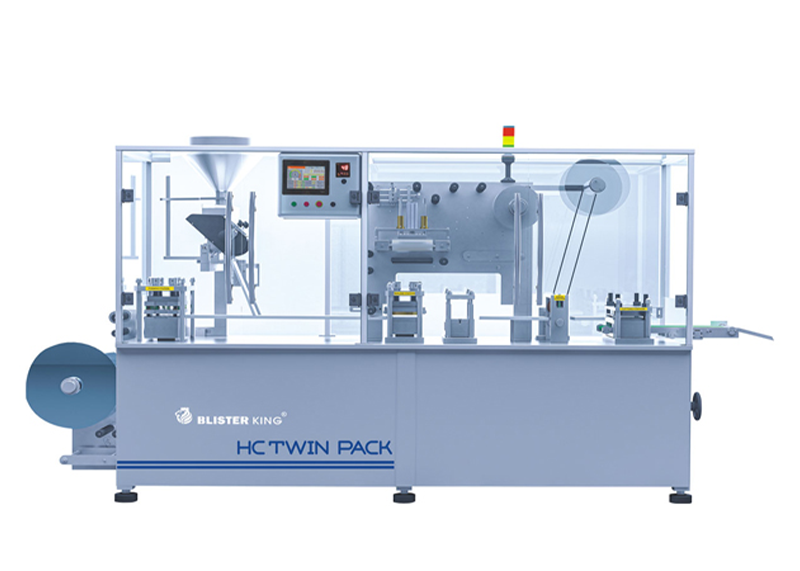

RELATED PRODUCTS